Medasia Marine CEO David Farmer on the new Abu Dhabi Facility, Sustainable Shipbuilding, and more

This month’s dispatch welcomes Mr. David Farmer, CEO of superyacht services boutique company Medasia Marine. Operating out of Abu Dhabi, the chief executive downloads me on the launch of Medasia Marine’s new shipbuilding facility, and the incorporation of green technologies that are revolutionising the industry.

Oman has made progress with the development of two new marinas in Muscat and the northeastern city of Sur. Meanwhile, Dutch shipyard Heesen has appointed a new CEO, the latest change under the yard’s new ownership under entrepreneur Laurens Last.

All the best,

Faisal

There’s an old maxim that goes “the day you stop learning is the day you stop growing.” For Mr. David Farmer, CEO of Medasia Marina, it is a philosophy that he has subscribed to as he navigated over three decades in the maritime industry, and one that has propelled the superyacht-services company into new barrier-breaking heights. Headquartered in Abu Dhabi, with outposts in Malta and the United Kingdom, Medasia Marine has been providing the yachting industry with an array of services for over 25 years, from sales, charter, procurement and storage facilities, along with the Center for Sustainable Shipbuilding (CSSB), the company’s training and development arm paving the way for a more environmentally friendly boating industry.

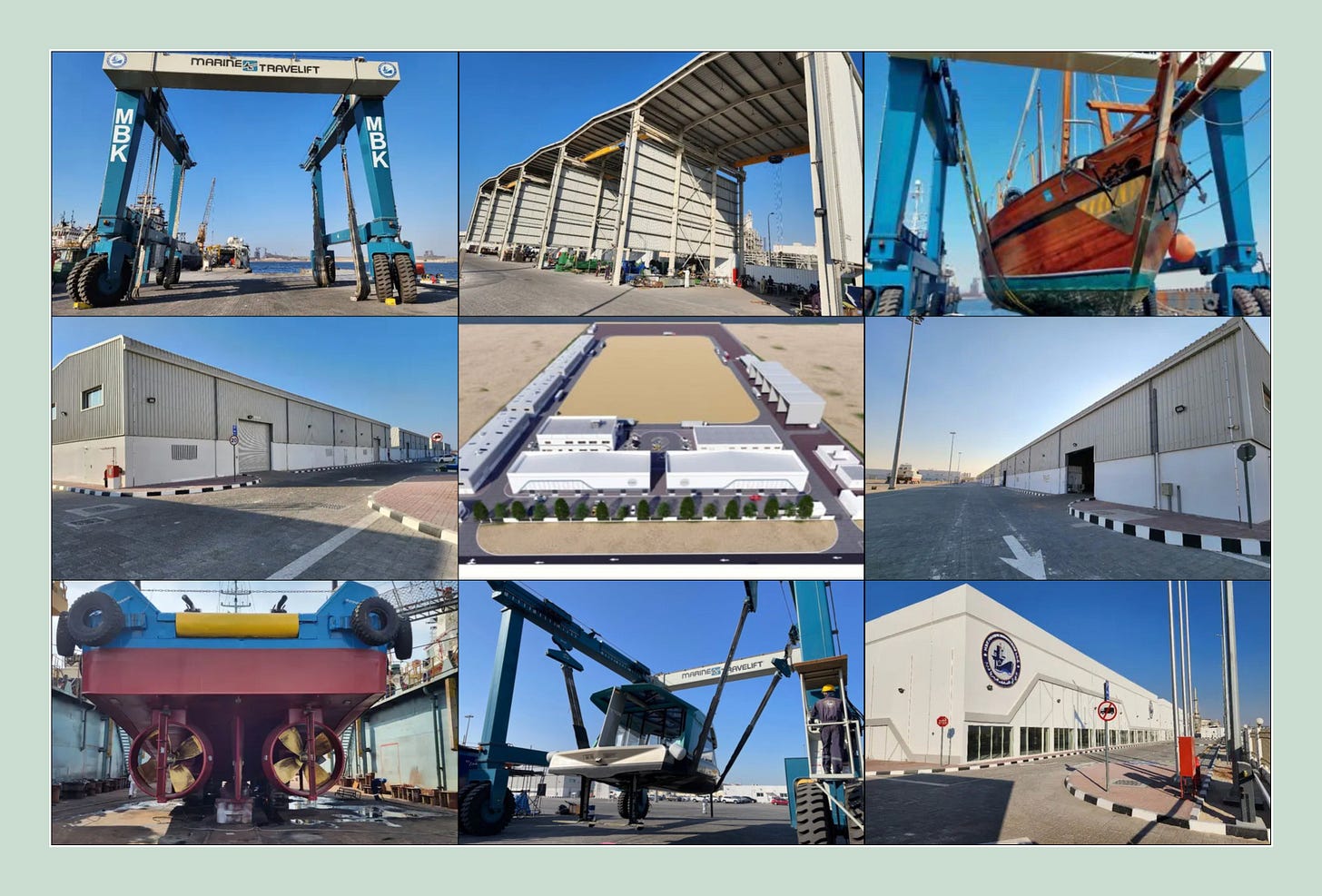

And now, under the steady hand of Farmer, the company has recently celebrated the launch of a new facility located in Abu Dhabi’s Industrial City. As part of MBK Marine’s 87,000 smq2 shipyard, Medasia Marine’s facility is well positioned to capture the Venn diagram overlap between refit services, new build fabrication and green shipbuilding. The operation finds a 2,000-ton floating dock, a 150m jetty and a heavy travel lift, while the facility boasts a host of green credentials, including hybrid electric propulsion, recyclable composites and lifecycle design, with six in-house specialists in services such as design, naval architecture, welding and carpenting.

Speaking to The Maritime Observer newsletter, the Chief Executive discusses the process behind launching the facility, the challenges and opportunities of making the yachting industry more sustainable, and the importance of education.

Congratulations on the new facility. How did plans to launch come about, and how far in advance did you plan it? Why did you settle on Industrial City?

We were looking at the manufacturing of our own products. Whilst we worked in the maritime industry for a number of years, I found myself in the UAE with some bespoke products.

We launched a sustainable arm to the business, and then it made sense to look at a collaborative program called “Make It In The Emirates”, where we exhibited at the recent expo in Abu Dhabi, and we were astonished by how many manufacturing companies there were producing goods in the Emirates for export. For us, we needed to manufacture but we also needed to be able to supply to the local market, and also to globally export.

For the products we wanted to manage, furnish and manufacture, it was key that we had access to the water and also access to global logistics.

Sustainability is a key part of the company’s ethos. Can you tell us more about Medasia’s green technologies and how they will impact marine services of the future?

From the floating structure side, which are essentially floating sustainable villas, and a solar pod - a habitable, sustainable unit, we’ve spent a number of years researching sustainability ESG programs, ethically-sourced materials that are suitable to create such a product, and we wanted to start from the waterline upwards.

It’s very difficult to produce an entirely sustainable product, and the word is misused - as I think everyone on the planet now understands - so we wanted to make sure we were creating something that had the right user cases, at the right materials.

For instance, we’re using a material for our hull sections, HDPE (high-density polyethene), which is recycled. This is the only material that exists on the planet that emits zero toxins to the marine life.

So just to begin, we’ve protected the marine life against toxins, and fibre is one of the worst polluters into the marine environment, as well as steel and anti-foul coatings, etc.. but when it comes down to HDPE, it’s the only product that is totally recyclable, virtually indestructible, and emits no toxins as materials. It’s already used widely in pipes for water services.

Medasia has been at the forefront of making this industry greener for some time now. This past December, you delivered the region’s first 100% electric X Shore 1 boat. How did that go, and where do you plan to take sustainable marine solutions in this region in the next few years?

The electric boat is working very well. It’s worked perfectly in the UAE. We were apprehensive about the water temperatures; you’re not putting a lithium in a car, you’re putting it in 35 degrees of Gulf water. Having it cooled has been quite challenging, and it took a lot of research prior to that. I do see that our next move in the sustainable EV/BV market space, when it comes to marine, is hydrogen.

I think now, there are two large superyachts launched this year and are presently cruising around the waters, operating very successfully. Until now, hydrogen has been something that we were quite cautious about.

I worked on the first hydrogen-powered boat over 35 years ago in Belgium, which was for a German designer, with fuel-cell technology. And up until now, I have always felt that it needed a lot more education in order to educate the public and the user for a user-friendly hydrogen-based model when it comes to maritime.

However, the two yachts that are being used are doing that for us. So it is clear proof that alternative fuels, whether it be hydrogen, methanol, etc, are now the way forward. So we would like to see, when we launch our first solar pod in November in Abu Dhabi, that it is run or assisted with hydrogen. That is something which we are working on day and night at the moment to be able to get that to fruition.

What do you think are the biggest challenges when it comes to pushing green technologies in the region, and do you think it is widely embraced or still hesitant?

Still very hesitant. I think that it will take at least another five years before we have different conversations regarding this topic. One has to pioneer where one believes it’s right. If nobody does it, nobody learns. Nobody understands the user case. It’s like everything else: you have to get equal.

The issue with yachts and floating structures is that you’re living on top of hydrogen. It’s not that you’re propelled in your car by it, because the propellant is behind you. When you’re living and cruising around in a yacht, it’s accompanying you. There are different psychological education factors that I believe need to be taken into consideration. And you can’t do that until you actually stay on board and work with it and live with it. Once you’ve done that, that’s a good enough user case to move forward.

A lot of the Emirates and other GCC members are all government remits for green hydrogen, which I think is great, however, trying to get it to dispense, to use it in an economical way, is becoming quite challenging. I see another five years before we can dispense it well.

Another component of The CSSB, Center for Sustainable Shipbuilding, is an initiative poised to cause real, positive change in the industry. How did that come about?

The CSSB is designed with the idea of forming a collaborative group of other like-minded professionals to educate everyone.

We set that up for two reasons. One, education and that goes hand in hand with the materials and products that we’re using to create a more green initiative. But if you don’t educate your workforce to work with that, and introduce the right materials, you won’t find that you can manufacture products if you haven’t got the skillset and the educational part of your team.

Whilst we look at the industry going forward, it’s very important that we educate the trades, whether it be yachting or commercial, all aspects of the marine industry, in skillset for the future way. There’s no doubt that shipbuilding is changing and has to change for a greener alternative. You won’t be able to do that unless you have the understanding and education of the skillset.

What about education on the consumer-facing side? How open is the client to pursuing greener alternatives, and why would they shy away from it?

I think the client has to be a specific client to identify the green refit. At the end of the day, refit has a bottom-line number.

Don’t forget the asset going in for refit is already, the numbers are already going through the owner's representative and the client, of course and how much it's going to cost him. So if it’s going to cost him another half a million to have a greener refit, then they are probably not going to choose that option. So it really is looking towards the shipyards and the contractor to make that happen.

We’re suffering a bit from greenwashing. Sustainable is a big word, and it’s being used quite a lot in the wrong ways. It’s a bit like the word luxury, they are overused words. You can tack on to everything and anything you need. We do it, but when we say luxury, we work out the luxury side of it. And when we do say sustainable, we do mean that, and we can back that up by the list of materials that we use and the ESG that we would put in place to be able ot manage all that at the time.

Refit services are gaining prominence in the region, we are seeing the construction of multiple facilities in Saudi Arabia, Qatar and the Emirates to cater to this market. Where do you think the demand is coming from, and who is it coming from? Foreign-flagged yachts?

It’s quite challenging to get a foreign-flagged vessel up into the region, let alone refit it. I think it’s the local owners. The visiting yacht, or commercial vessel that was here, yes, there will be a certain proportion that will have an interest in that, but it’s how you define a green refit. I think that’s yet to be exactly determined.

What’s next for Medasia beyond the region?

Very soon in the US. We have some projects which are underway now. The US will be officially unveiled in October at the Fort Lauderdale International Boat Show.

You have been in the industry for some time. What excites you these days?

The launches over the last couple of weeks have been interesting in their design ethos and technology. I am an engineer, and I thrive on seeing new technology. I really think the industry has moved in big steps with the design and technical achievements, with some larger shipyards.

I think that’s fascinating and will certainly propel the yachting industry to lots of conversations. And I see that going on for the rest of the year, and I see new ships that are being built, which will be further advanced. And there seems to be an appetite for alternative fuel sources, coupled with some beautiful designs. We look forward to seeing that.

What is one piece of advice that you live by:

You've got to learn. If you don’t look, listen and learn, then you don’t thrive. You’re not able to evolve at any level of industry - whether you’re starting in an internship, or you’re mid-degree qualified or a veteran.

This interview has been edited and condensed for clarity.

Oman’s Khor Grama Project Taps Firm to Design 75-Berth Yacht Marina

The Ministry of Transport, Communications and Information Technology in Oman has appointed multi-disciplinary consulting firm Meridian Engineering Consultancy (MEC) to design and supervise the construction of a superyacht marina for the Khor Grama development project.

Heesen Yachts Names Jeroen van der Meer as New CEO

Dutch shipyard Heesen Yachts has announced the appointment of Jeroen van der Meer as Chief Executive Officer. The appointment, which will be effectuated in September 2025, comes as the latest change in the company following its acquisition by entrepreneur Laurens Last in April 2025.

Oman’s Al Khuwair Project Starts Bidding Process for Marina Design & Construction

Oman’s Ministry of Housing and Urban Planning has started the bidding process for the design and construction contract of the Al Khuwair project marina. Tender documents, made available in May 2025, reveal that the package includes the design and construction of a 1500-meter main breakwater, two low-crested breakwaters of 500 and 290 meters, respectively, and pipe protection works.